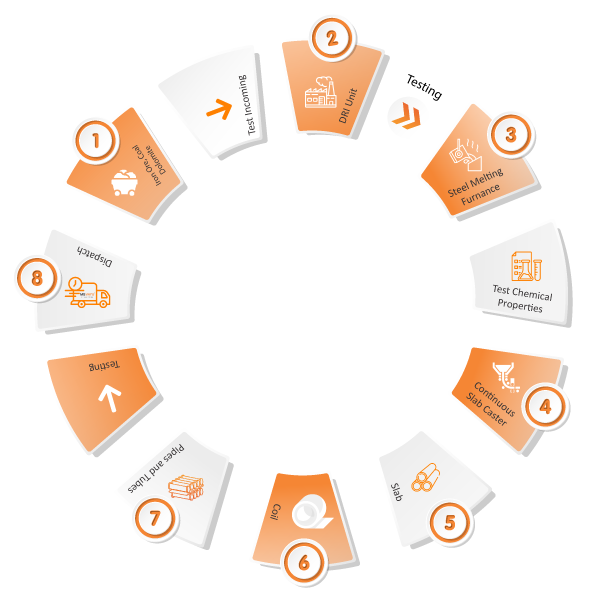

Our commitment to superior product quality and exceptional service is grounded in our advanced Mines to Mills integrated steel plant. This comprehensive integration allows us to maintain meticulous control over every stage of the production process, from raw material extraction to final product delivery. By overseeing both upstream and downstream operations, we ensure that our steel surpasses BIS standards, delivering exceptional quality and performance. This integrated approach also enables us to manage quality, costs, and delivery timelines effectively.

Steel at MS VAYU is produced through a sophisticated process in our state-of-the-art integrated steel plant. We start with the primary steelmaking route using high-grade iron ore. The iron ore is processed in our furnace to produce molten steel, which is then continuously cast into billets.

The virgin steel we produce is of exceptional quality, free from harmful impurities, ensuring consistent and reliable properties in our pipes. The cast billets are hot-rolled in fully automated pipe mills, equipped with advanced process monitoring devices to guarantee uniform properties throughout each pipe. Our pipe mills are outfitted with the latest pipe technologies and utilize state-of-the-art tungsten carbide rolls instead of traditional steel rolls, providing excellent dimensional tolerance and surface finish.

The meticulous process and advanced technology result in steel with superior strength, fine finish, and overall high quality. Our integrated approach not only ensures optimal product performance but also supports innovation and continuous improvement in steel production.

We are dedicated to sustainable practices, employing eco-friendly technologies and processes that minimize waste and reduce environmental impact. Our integrated steel plant operates with efficiency and precision, aligning with our commitment to environmental stewardship and responsible manufacturing.

Our ability to control every aspect of production allows us to meet diverse customer requirements effectively. By ensuring high-quality standards and timely delivery, we provide solutions that meet the specific needs of our clients, enhancing their satisfaction and fostering long-term relationships.

In summary, our Mines to Mills integrated steel plant is the cornerstone of our capability to produce steel that excels in quality, strength, and consistency, supported by our commitment to sustainability and customer satisfaction.

At MS VAYU, MS pipes and tubes are produced using high-quality raw materials sourced from top mines around the world. The primary raw materials include iron ore, coal, and dolomite.

This thorough manufacturing process ensures that every product meets our high standards of quality and performance.